Technology

Advanced technology

Barazzoni has always concentrated on researching new technologies to make its products more resistant and performing.

Steel: a question of impact

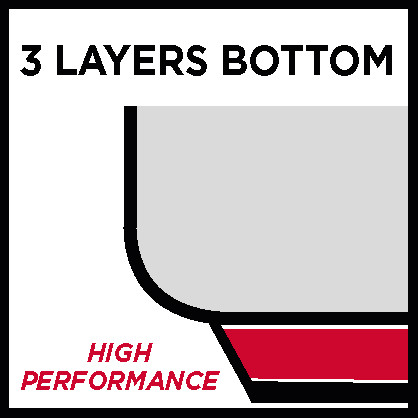

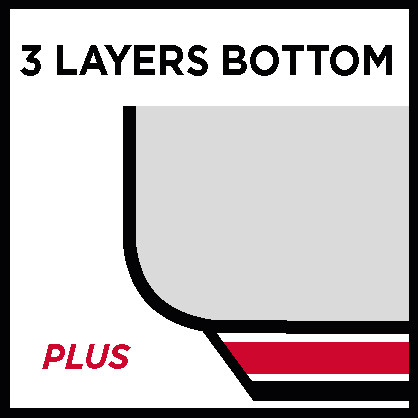

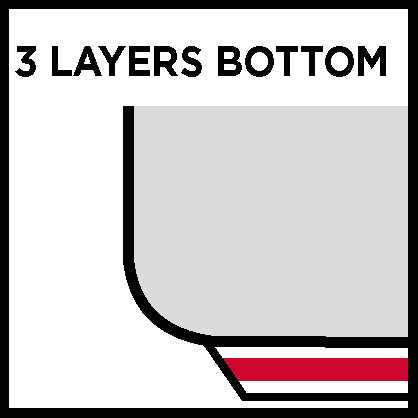

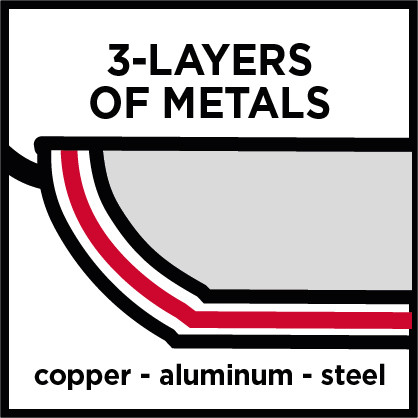

Barazzoni is one of the first companies to introduce the Impact Bonding system, an innovative method that involves the indissoluble union of the 3 discs (steel-aluminium-steel) that make up the bottom of the pan. This avant-garde system generates a molecular interpenetration between the three layers, making the product resistant, able to guarantee an even heat diffusion and to be used on all heat sources, including induction.

- 3-layer bottom steel - aluminium - steel

- Perfect anchorage of the base to the pot body

- Optimum heat distribution across the entire surface thanks to the extra-thick aluminium layer

- Suitable for all heat sources, including induction

- 3-layer bottom steel - aluminium - steel

- Perfect anchorage of the base to the pot body

- Optimum heat distribution across the entire surface thanks to the extra-thick aluminium layer

- Suitable for all heat sources, including induction

- Aluminium bottom encapsulated in a steel disc to enhance the thermal conductivity of steel

- The aluminium layer allows heat to spread evenly over the entire base and reduces the risk of burns

- Trimetal line available in 2 versions: steel or copper

- Guarantees perfect cooking thanks to the intermediate layer of aluminium that spreads the heat evenly over the entire surface

- The bottom of the pan is an extension of the body itself

Pressure cookers: practicality and safety

Barazzoni has been producing pressure cookers since the 1960s, making them synonymous with quality, safety and well-being. The pressure cooker speeds up cooking times considerably, saving time and energy. The quality of the product ensures that food is cooked to perfection, enhancing its flavour without altering its nutritional principles.

Bayonet system

- Opening/closing mechanism is via a lever handle

- 1- or 2-pressure operating valve: operating and venting adjustments

- Up to 30% reduction in cooking time and energy saving

- Main safety systems: pressure indicator (lever lock) and safety valve

Jaw system

- The opening/closing mechanism is effortless, with one hand in any position

- 2-pressure operating valve: innovative Dual System cooking device for differentiated cooking according to foodstuffs

- Up to 45% reduction in cooking time and energy saving

- Double safety: lever lock (pressure indicator function and safety valve function) and safety device that ensures discharge of excess pressure in case of anomalies

Aluminium coatings: quality layers

Thanks to its high thermal conductivity and low specific weight, aluminium gives lightness and excellent handling to cooking utensils while ensuring optimum results in food preparation. Aluminium's properties are enhanced by its non-stick finish, making it ideal for short cooking and browning. It is also an environmentally friendly material: 85% of an aluminium pan can be recycled.

- Latest generation, top of the range coating

- Rough and porous surface that enhances the non-stick characteristics

- The "hard" core of the non-stick coating is combined with the next 4 layers to create a 5-layer coating

- For a very demanding public aiming at the maximum

- Innovative, latest-generation DIAMANTECH inner coating

- Reinforced with titanium particles and enriched with 33 carats of natural diamond powder*

- 5 layers applied by spray technology with 30% more thickness

- Equipped with a non-stick layer

- For a particularly knowledgeable and demanding public

- Standard quality products

- Non-stick coating designed for normal use

- Several layers applied by spray or contact transfer technology

- Reduced aluminium thickness

- For a dynamic audience that pays attention to quality

- High quality non-stick coating

- Reinforced with extra Marmotech® particles

- Lasts up to 5 times longer than a traditional coating

- 5 layers applied with spray technology

- The pan bodies are in aluminium with differentiated thicknesses to guarantee optimum heat distribution

- For a particularly knowledgeable and demanding public

- High quality non-stick coating

- Extremely resistant and super reinforced with Marmotech® particles

- 6 layers applied with spray technology

- The pan body is equipped with a layer of non-stick coating and a reinforced outer surface

- For a particularly knowledgeable and demanding public

- High quality non-stick coating

- Extremely resistant and reinforced with Marmotech® particles

- 5 layers applied with spray technology

- The pan bodies are in aluminium with differentiated thicknesses to ensure optimum heat distribution

- For a particularly knowledgeable and demanding public